|

Introduction to the firm 1 - Forge

Our firm is equipped with 3 hammers, to forge bars, blocks, discs, center tit discs, rings.

Main alloys we forge are Nickel, Titanium, Zirconium alloys, and pure Copper.Each alloy (X750, 718, K500) can be heat treated as per customers´ specifications.

A part of the forge 2 - Machining

We are equipped with slide lathes, vertical lathes and a drilling-machine to make rough pieces.

We also are able to make finished pieces in all our metals with the intervention of our partners equipped with numerical control machines.

Mandrel lathe ě 450 length 2000 Heat treatments

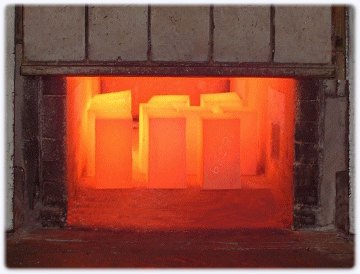

We have ovens which enable solution heat treatment, quenching and structural hardening. On request we can propose graphics of the temperature registration of the heat treatments.

Heat treatment oven, phase 1. 4 - Trading

Since about ten years, CARLIER SA is specialized in trading of bars from ě 4 to ě 250 mm. We take the engagement of delivery within 24 to 48 h.Please contact us for yor needs in Nickel, Copper, Titanium and Zirconium alloys.

Moreover, CARLIER SA is a rare firm in Europe to have stock of bars, tubes and sheets in OFHC Copper.

Main stock hall 5- Cutting up.

We are equipped with ribbon saws to enable the cuts corresponding to your requirements in bars and billets from ě 10 to ě 450.

We also have cutting-machine for sheets.

Ribbon saw with capacity of ě 450. 6- Controls and shipments

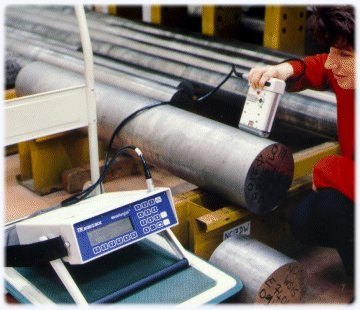

Before every shipment a carefull control is made by our quality responsible.

Before putting on stock, metal is tested with an alloy analizer to confirm the alloy.

Our firm is a partner of various laboratories (COFRAC certified) to proceed at tensile strength, impact tests, G28B tests, US controls, dye penetrant inspection, as per our customers´ specifications.

Alloy analyzer by XRF (X ray fluorescence) |